The customer

The Baloise Group based in Basel is the third-largest Swiss all-line insurance services provider to both the commercial and private sectors. With 7,300 employees the group is represented in Germany – Basler Versicherungen, and further subsidiaries in Belgium and Luxemburg.

The goal: outsource software packaging with deployment via SCCM

As part of a Windows 10 migration, Baloise intended to outsource software packaging services to a specialized service provider.

Baloise plans to distribute the applications via SCCM and, therefore, required software packages created and based on Windows Installer technology. Also, to process upstream and downstream actions of the installation routine, Powershell wrappers are used. The requirement is to deliver all packages as SCCM application objects for distribution. With the support of an on-site packaging consultant, the primary services provided remotely with a dedicated team from the packaging factory. The Windows 10 migration goal is to create a total of 600 software packages for the four countries; Switzerland, Germany, Belgium and Luxembourg. After the project phase, operational packaging will continue to be supported.

The implementation by Apptimized

During the initial steps, Apptimized carried out an extensive mobilization phase with detailed agreements on future cooperation via a SPOC. During this mobilization phase, the processes, responsibilities, packaging standards, test requirements and much more were discussed and agreed.

To better coordinate and take over various process steps, we use an on-site packaging consultant. The consultant takes on the following tasks on-site at the customer’s premises, either partially or entirely:

- Ordering and coordinating remote packaging orders

- Single point of contact for the customer

- Implementation of the finished packages in SCCM

- Coordination of the acceptance of the finished packages

- Packaging applications that are not suitable for remote creation

Using the Apptimized Portal the commissioning of software packages for the Packaging Factory and the reporting is managed in one central place. This enabled Baloise always to have an overview of the current packaging status. This workflow management system ensures smooth communication between Baloise and Apptimized. It offers other advantages, such as an order’s real-time tracking.

With the Apptimized Discovery module’s help, the customer’s application managers create the installation instructions for the respective packaging jobs. With this innovative, partially automated solution, we enable even non-IT-savvy users to create high-quality installation instructions for the applications that are understandable for everyone.

Remote packaging and internal quality assurance take place entirely in the Apptimized Cloud. As a result, Baloise no longer needs its packaging infrastructure for the vast majority of orders and benefits from the advantages of the Apptimized Cloud:

- Low infrastructure costs

- Guaranteed availability

- Seamless and fast processes for the packaging process

- A small number of products remain within the customers on-site packaging infrastructure for processing

The Apptimized web interface enables the seamless delivery of the created package, including completed tests, packages with Powershell wrappers and SCCM application object.

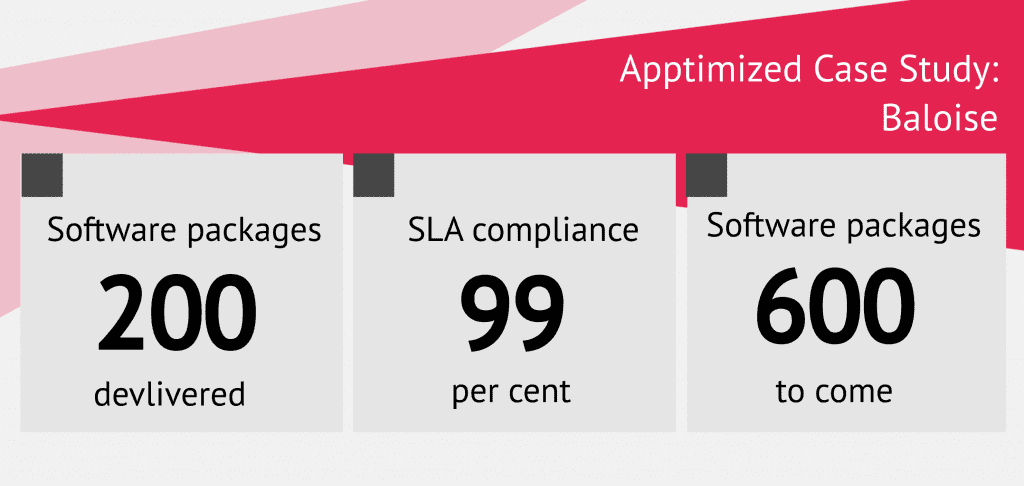

We currently have over 200 software packages created and delivered, with no significant quality defects or SLA violations. So far, we have achieved more than 99% quality and SLA compliance.